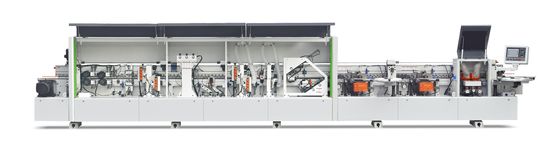

Automatic High Gloss Boards Edge Bander For Kitchen Cabinet Factory HD771JD

Features

1. This edge banding machine can work on materials of MDF, blockboard, solid wood board, particleboard, polymer door panels, plywood, etc.

2. With the functions of pre-milling gluing, end cutting, rough trimming, fine trimming, corner trimming, scraping, and buffing, it can achieve a smooth and fine working finish.

3. With better parts, it is stable, reliable, and durable

4. It is especially suitable for medium and large furniture manufacturing factories.

5. Per-milling---Trim equipment with double trim blades works on the wave effect that is caused by a precise saw.

6. Gluing---Glue unit configured with a special structure to gelatinize the panels and coat materials uniformly, which ensures a more solid conglutination.

7. End trimming---End trimming unit through a precise guide track movement, configured with automatic tracking and high-frequency motor fast cutting structure to ensure the cutting surface smoothly.

Specification

|

Items

|

Specification

|

|

Total power

|

21.6kw |

|

Feeding speed

|

14-20-23m/min

|

|

Edge banding thicknes

|

0.4-3mm

|

|

Board thickness

|

10-60mm

|

|

Board length

|

≥120mm

|

|

Board width

|

≥60mm

|

|

Working pressure

|

0.65Mpa

|

|

Overall size

|

8190x900x1650mm

|

Click the below link for the video of our machines:

About our company

One-stop solution for interior furniture equipment and wooden door equipment

HOLD Machinery was founded in 2004, focusing on the development of a full range of furniture machinery equipment and wooden door machinery and equipment, providing furniture and wooden door enterprises with solutions for whole factory planning and automatical production lines, providing customers with excellent quality, efficient and stable products, and high-quality service.

HOLD Machinery has served the majority of furniture and wooden door enterprises in more than 40 countries and regions around the world and has won wide admiration from customers.

FAQ:

1. Do you have the machine in stock?

Sorry, we don't have the machine in stock, edge banding machine has many options such as voltage, speed, function, and so on, So it's hard to prepared samples.

2. How long is your delivery time?

For our standard model, the delivery time is around 1.5~2 months. For the customized model, the delivery time is around 2~3 months. It depends on the client's project and quantity.

3. Do you have a factory?

Yes, we have our own factory and we promise direct sales at a competitive price. Welcome to visit our factory at any time.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!