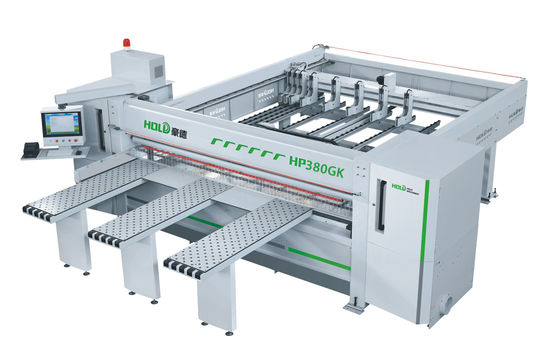

Automatic Computer CNC Beam Saw Machines For Wood Cutting HP380GK

Quick Info.

|

parameters and specifications

|

HP380GK |

|

Cutting length

|

3780mm |

Slot saw shaft motor power

|

2.2kw

|

|

Sawing width robot stroke

|

3780mm |

working voltage

|

380 volts /50 Hertz

|

|

Maximum height of blade

|

100mm Intelligent elevator

|

bench height

|

920mm

|

|

Big saw blade:1 pcs

|

400 x 4.4 x 75 x 72 teeth

|

Number of Griper

|

10 pcs

|

|

Slot saw blade:1 pcs

|

160 x 4.4 / 5.4 x 45 x 24T

|

air bearing table

|

3 pcs(1280 x 430)

|

|

Saw socket forward speed

|

5 - 100M/MIN

|

Air floating platform high pressure fan

|

1pcs

|

|

Saw socket return speed

|

100M/MIN

|

Air compressed

|

6Par

|

|

Forward speed of manipulator

|

0--100M/MIN

|

Total air consumption

|

150L/min

|

|

Backward speed of manipulator

|

100M/MIN

|

Minimum dust extraction speed

|

26m/sec

|

|

Control system PLC

|

LS high-speed PLC

|

negative pressure,at least

|

1200pa

|

|

Hyper Crystal LCD

|

PC |

Input air capacity for dust collection

|

4400m3/h

|

|

side-pressing device

|

yes

|

Diameter of dust extraction pipe(2pcs)

|

125×2pcs/100×2pcs

|

|

Main sawing shaft motor power

|

18.5kw

|

|

|

Standard configuration and advantages of the machine:

- Solid double side rails for precision and durability

- Rack and pinion drive without lubrication

- AC servo motor drive The robot pusher runs at high speed, accuracy, and high speed.

- Optional: Non-contact electromagnetic measuring system

- No wear, no maintenance, closed-loop measurement, high precision drive system.

- The robot is solid and reliable. It will not slip.

Cutting saw base: Heavy-duty body, multiple annealing, solid and durable, not easy to deform. Pressure beam:

-Aluminum alloy integral pressure beam: Perfectly press the plate on the machine table to ensure the stability of the sawing plate --

-Double-end rack and pinion synchronous pressure beam, evenly apply pressure to the entire machining surface --

- Minimal pressure beam opening amplitude, optimized dust removal, perfect sawing effect Saw seat: The saw seat adopts imported aluminum alloy structure. Advantages: Lifetime deformation resistance

- Rack and pinion drive: no lubrication required - Manual adjustment of the slot saw for quick and easy Optional: sheet optimization and label printing: transfer data via computer, print barcode, or QR code After the plate programming is optimized, the generated cutting program is directly transmitted to the electronic cutting saw through the network or the U disk is used to copy the data into the electronic cutting saw, which is convenient and quick, and improves work efficiency.

If want to know more about our products by video, please click the below link:

About our company

One-stop solution for interior furniture equipment and wooden door equipment

HOLD Machinery was founded in 2004, focusing on the development of a full range of furniture machinery equipment and wooden door machinery and equipment, providing furniture and wooden door enterprises with solutions for whole factory planning and automatical production lines, providing customers with excellent quality, efficient and stable products, and high-quality service.

HOLD Machinery has served the majority of furniture and wooden door enterprises in more than 40 countries and regions around the world and has won wide admiration from customers.

FAQ:

1. Do you have the machine in stock?

Sorry, we don't have the machine in stock, edge banding machine has many options such as voltage, speed, function, and so on, So it's hard to prepared samples.

2. How long is your delivery time?

For our standard model, the delivery time is around 1.5~2 months. For the customized model, the delivery time is around 2~3 months. It depends on the client's project and quantity.

3. Do you have a factory?

Yes, we have our own factory and we promise direct sales at a competitive price. Welcome to visit our factory at any time.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!