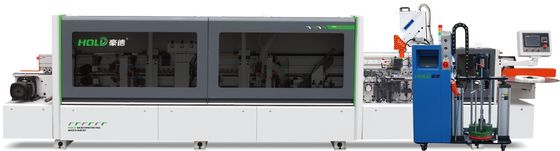

PUR Glueing System Door Edge Banding Machine HD730JPUKQ

Features-- With the PUR gluing system, the glue line will be more thinner and longer service time.

This machine is specially designed and exclusive for foreign market by us, which is multifunction but favorable price. It is used for MDF, wooden boards, and shaving boards. It can complete the processes of feeding workpiece, feeding coiled material, edging, end cutting, fine trimming, scraping, and buffing. It can achieve the level as same as foreign machines and the price is favorable. It is especially suitable for the factory producing board.

1. Edge Banding Material: PVC, Melamine, ABS, Veneer, Solid Wood Strip, etc

2. Workpiece: Plywood, Fireboard, MDF board, Solid Wood, Particleboard, etc.

3. Imported quality engines and electrical components.

4. Serialized products, a wide range of selection for customers.

5. High precision&efficiency.

Product specification

|

Name

|

wood door edge banding machine |

|

Model

|

HD730JPUKQ |

|

Electrical lift

|

Yes

|

|

Total power

|

17.2kw |

|

Overall dimension

|

6410x900x1700mm |

|

Feeding speed

|

0-23m/min (with corner rounding )

|

|

Edge tape width

|

10-60mm

|

|

Edge tape thickness

|

0.4-3mm

|

|

Panel thickness

|

9-60mm

|

|

Panel width

|

≥60mm(Min.)

|

|

Working pressure

|

0.7mpa

|

Please click below for more information

About our company

One-stop solution for interior furniture equipment and wooden door equipment

HOLD Machinery was founded in 2004, focusing on the development of a full range of furniture machinery equipment and wooden door machinery and equipment, providing furniture and wooden door enterprises with solutions for whole factory planning and automatical production lines, providing customers with excellent quality, efficient and stable products, and high-quality service.

HOLD Machinery has served the majority of furniture and wooden door enterprises in more than 40 countries and regions around the world and has won wide admiration from customers.

FAQ:

1. Do you have the machine in stock?

Sorry, we don't have the machine in stock, edge banding machine has many options such as voltage, speed, function, and so on, So it's hard to prepared samples.

2. How long is your delivery time?

For our standard model, the delivery time is around 1.5~2 months. For the customized model, the delivery time is around 2~3 months. It depends on the client's project and quantity.

3. Do you have a factory?

Yes, we have our own factory and we promise direct sales at a competitive price. Welcome to visit our factory at any time.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!