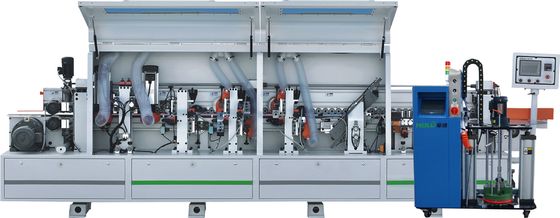

Automatic Edge Banding Machine Edge Bander For Woodworking Machinery HD620LLPU

This Edge banding machine is suitable for the solid wood board, fiberboard, particleboard, and other sheet metal workpiece straight edge, edge material can be used solid wood, PVC, melamine, veneer, etc

Features

1. Edge's chips remove the device: Solve the problem that the edge's chips affect the normal operation of the glue scraper, or directly winds the polishing unit to cause the stuck and burned motor.

2. Glue scraper: Remove excess hot melt adhesive on the surface of the workpiece.

3. Cleaner spraying device: dilute residual hot melt adhesive, easier to clean.

4. The rubber-coated auxiliary roller will not damage the surface of the panel so that the narrow panel runs stably on the conveyor belt and the edge banding is more stable.

5. Realize fast switching of glue pot to meet the mutual switching of different color glues

6. This is a high-speed and high configuration edge banding machine, which has the advantages of automation, high efficiency and high precision.

Quick information

| Thickness of the wood: |

10-60mm |

| Edge tape thickness: |

0.4-3mm |

| Min width of the wood: |

≥80mm |

| Min length of the wood: |

≥120mm |

| Feeding Speed: |

13m/min--18m/min-23m/min |

| Air Pressure: |

0.6Mpa |

| Voltage: |

380V/50HZ 3Phase or customize |

| Feeding Gluing motor: |

0.37kw 50HZ 1400RPM |

| Head end Cutting motor: |

0.35kw * 2 200HZ 12000RPM |

| Fine Trimming motor: |

0.55kw * 2 300HZ 18000RPM |

| Polishing motor: |

0.18kw * 2 50HZ 2800RPM |

| Glue tank heating power: |

1.5kw |

| Assistant heating power: |

0.12kw |

| Panel feeding motor: |

1.5kw |

| Total Power: |

21.8kw |

If you want to know more detail about this machine, please contact me, For more information about our products, please click the below link:

About our company

One-stop solution for interior furniture equipment and wooden door equipment

HOLD Machinery was founded in 2004, focusing on the development of a full range of furniture machinery equipment and wooden door machinery and equipment, providing furniture and wooden door enterprises with solutions for whole factory planning and automatical production lines, providing customers with excellent quality, efficient and stable products, and high-quality service.

HOLD Machinery has served the majority of furniture and wooden door enterprises in more than 40 countries and regions around the world and has won wide admiration from customers.

FAQ:

1. Do you have the machine in stock?

Sorry, we don't have the machine in stock, edge banding machine has many options such as voltage, speed, function, and so on, So it's hard to prepared samples.

2. How long is your delivery time?

For our standard model, the delivery time is around 1.5~2 months. For the customized model, the delivery time is around 2~3 months. It depends on the client's project and quantity.

3. Do you have a factory?

Yes, we have our own factory and we promise direct sales at a competitive price. Welcome to visit our factory at any time.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!