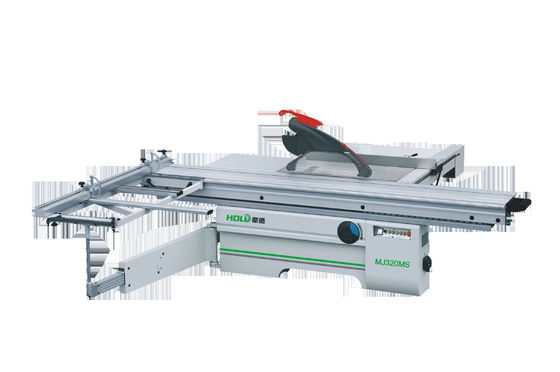

Automatic Wood Cutting Machine MJ320M

1. The main structural feature of the precision panel saw is the use of two saw blades, namely the main saw blade and the scoring saw blade. When cutting, the scoring saw cuts ahead of time, and first cuts a groove with a depth of 1 to 2 mm and a width of 0.1 to 0.2 mm thicker than the main saw blade on the bottom surface of the processed board to ensure that The edge of the cutting edge will not tear when the main saw blade is cut, so as to obtain good cutting quality.

2. The scoring saw blade has a small diameter, usually around 120mm, and is driven by a separate motor. It is required that the scoring saw blade and the main saw blade are aligned in the same vertical plane. The diameter of the main saw blade is generally 300-400mm, which is driven by the main motor through the V-belt.

3. Circular rod structure with chromium plating, compared with the past linear ball sliding table, has high positioning accuracy, long service life and promotes smoothness.

4. Upgrade large motor, the machine uses a pure copper motor, the default main motor is 4kw, the scoring motor is 0.75kw. If you need to cut solid wood and other plates, you can customize a 5.5kw+1.1kw large motor.

5. The ruler to adopt the European style large ruler, stable and non-displacement, effectively ensure the precision in the cutting process of the board.

6. Main and scoring saw blade first by a scoring saw blade to open a line, followed by the main saw blade can be easily cut with high precision to prevent chipping burrs.

7. The machine saw blade adopts an electric lifting system, which is more accurate than a hand-cranked saw blade. The machine can also add functions such as electric tilt and a digital display to ensure accurate adjustment of the angle.

Technical specifications

| Overall Dimensions |

3200x3150x900mm |

| Sliding Table Size |

3200x375mm |

| Length of Cut |

3100mm |

| Width of Cut Between Saw Blade and Rip Fence |

1250mm |

| Height of Cut |

80mm(45°Max 55mm) |

| Saw Blade Diameter |

305mm |

| Scoring Blade Diameter |

120mm |

| Main Saw Blade Speed |

4000/6000rpm |

| Scoring Saw Blade Speed |

8000rpm |

| Saw Spindle Diameter |

30mm |

| Scoring Spindle Diameter |

20mm |

| Main Motor |

5.5kw |

| Scroring Saw Motor |

0.75kw |

| Main Saw Blade Titling Angle |

45°~90° |

| Net/Gross Weight |

700/800kg |

| Packing Size |

2180*1050*980mm |

| 3250*440*270mm |

Configuration description

Operation control system

European style horizontal guiding ruler

Stable without displacement, effectively ensure the precision of the plate cutting process.

Aluminum alloy medium scale

It is made of high-strength extruded aluminum alloy, which has strong stability and high precision.

Double saw blade design + high-speed motor

Double saw blade: the small saw is responsible for marking, and the big saw is responsible for cutting so that the cutting plate will not produce the phenomenon of edge collapse and burr.

High-speed motor: 5.5kW and 0.75KW motor, strong power, long service life.

Check the below link for more videos about our machines.

About our company

One-stop solution for interior furniture equipment and wooden door equipment

HOLD Machinery was founded in 2004, focusing on the development of a full range of furniture machinery equipment and wooden door machinery and equipment, providing furniture and wooden door enterprises with solutions for whole factory planning and automatical production lines, providing customers with excellent quality, efficient and stable products, and high-quality service.

HOLD Machinery has served the majority of furniture and wooden door enterprises in more than 40 countries and regions around the world and has won wide admiration from customers.

FAQ:

1. Do you have the machine in stock?

Sorry, we don't have the machine in stock, edge banding machine has many options such as voltage, speed, function, and so on, So it's hard to prepared samples.

2. How long is your delivery time?

For our standard model, the delivery time is around 1.5~2 months. For the customized model, the delivery time is around 2~3 months. It depends on the client's project and quantity.

3. Do you have a factory?

Yes, we have our own factory and we promise direct sales at a competitive price. Welcome to visit our factory at any time.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!