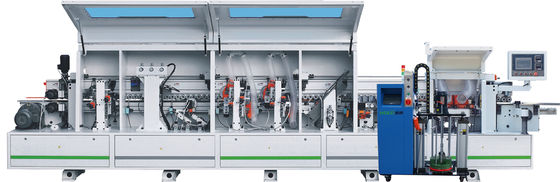

Linear Edge Banding Machine HD621JPUD with PUR gluing pre-milling and corner rounding.

Features:

1. As we know, if using the EVA glue for the edge banding, it would have the glue line, especially for the light color panel. But with the PUR gluing unit, can improve this problem, just need a very thin glue coating, then the edge can be stick to the panel very well, and the glue line is thinner.

2. PUR glue has the feature that if it was combined with the moisture in the air, it can't be melt again, So, it has very stable physical properties,

3. If you looking for an edge bander for high-end products, this would be absolutely better choice for your products.

4. Machine has equipped with pre-milling rough trimmer fine trimmer and corner rounding, suitable for all kinds of edge banding.

Technical specifications:

| 1. Model NO.: HD621JPUD |

|

2. Certification: CE

|

|

3. Panel Thinkness: 10-60mm

|

|

4. Min.length panel: 120mm

|

|

5. Min.width panel: 60mm

|

|

6. After-sales Service: 1 Y

|

|

7. Tapethickness: 0.4-3mm

|

|

8. Control system : LS -Korean

|

| 9. Guide Rail:China |

|

10. Panelthickness:12-60mm

|

|

11. Workpiecethickness:10-60mm

|

|

12. Conveyor Motor: 2.2Kw

|

|

13. Panel Preheating Power: 0.3 Kw

|

|

14. Glue Melting Power: 1.5 Kw

|

|

15. Panel Preheating Motor:0.3 Kw

|

| 16. Packing :Plywood Box with Strength Film |

|

17: Overall size: 7200mm*900mm*1700mm

|

|

18. Origin: GuandDong China

|

|

19. HS Code: 8465940000

|

More Details:

For understanding more about our machine, please check the below link to Youtube:

About our company

One-stop solution for

interior furniture equipment and wooden door equipment

HOLD Machinery was founded in 2004, focusing on the development of a full range of furniture machinery equipment and wooden door machinery and equipment, providing furniture and wooden door enterprises with solutions for whole factory planning and automatical production lines, providing customers with excellent quality, efficient and stable products, and high-quality service.

HOLD Machinery has served the majority of furniture and wooden door enterprises in more than 40 countries and regions around the world and has won wide admiration from customers.

FAQ:

1. Do you have the machine in stock?

Sorry, we don't have the machine in stock, edge banding machine has many options such as voltage, speed, function, and so on, So it's hard to prepared samples.

2. How long is your delivery time?

For our standard model, the delivery time is around 1.5~2 months. For the customized model, the delivery time is around 2~3 months. It depends on the client's project and quantity.

3. Do you have a factory?

Yes, we have our own factory and we promise direct sales at a competitive price. Welcome to visit our factory at any time.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!